Sheet Metal Fabrication Rapid Manufacturing

For rapid manufacturing in sheet metal fabrication, we provide services ranging from single part prototypes to full production runs.

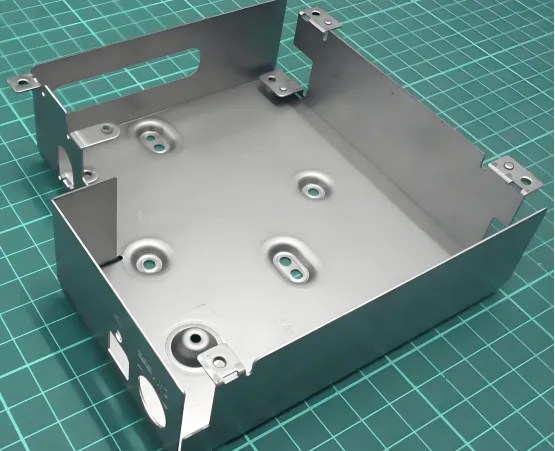

Sheet Metal Fabrication

Sheet metal parts fabrication involves shaping metal sheets into functional prototypes or final products. The process begins by forming the metal into the desired shape using various manufacturing techniques. Completing the product typically requires multiple steps, including cutting, forming, punching, surface treatment, and assembly.

Sheet Metal Parts Process

The sheet metal fabrication process involves cutting, forming, and punching metal sheets into the required shapes. Often, multiple fabrication techniques are employed to achieve similar outcomes. The choice of cutting machine is determined by the mechanical design, geometry, material type, and thickness of the sheet metal, along with factors like lead time and required tolerances. We accommodate orders ranging from single prototypes to full production runs.

COMMON APPLICATIONS

Construction——Roofing and wall panels, window frames and door frames

Automotive——Body panels (doors, hoods, fenders)

Aerospace——Aircraft fuselage and wings, Engine components

METAL MATERIALS

Aluminium, Stainless Steel, Alloy steel, Titanium, Copper, Tool Steel

+ much more

Don’t miss out on our services!

When you’re ready, we can assist you in selecting the best options for rapid prototyping or production quantities. Reach out to us to start a productive collaboration and find effective solutions together.

Services

All our available services at the moment for you!

CNC Machining

High Precision, Efficiency Flexibility, Repeatability, Reduced Error

Sheet Metal Fabrication

Durability, Versatility Cost-Effective, Lightweight, High Strength

Surface Finishes

Corrosion Resistance, Increased Durability, Enhanced Hardness