CNC Machining Prototypes &

Production Parts

Supplying metal CNC prototype machined parts that are in line with your requirements. CNC machining services for precision components needed for high-volume, low-volume, or quantity market production parts requirements, including fast prototyping of one unit.

Metal

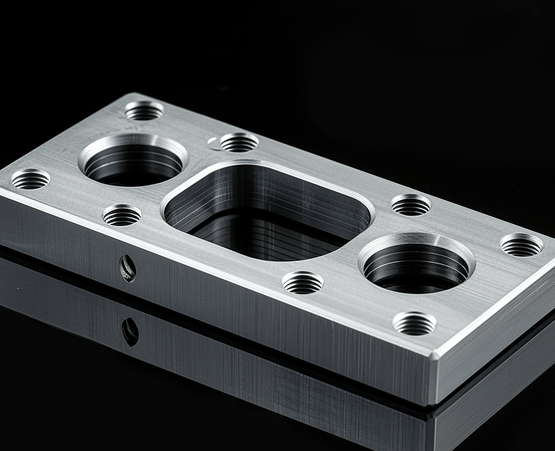

CNC PROTOTYPE MACHINED PARTS

CNC MILLING

In order to make finished products, CNC milling entails employing a cutting tool to remove raw material from a designated solid metal or plastic block selectively. This manufacturing process makes use of 5-axis indexed milling and 3--4 axis milling, which move or spin on various planes to enable the tool to operate at a variety of angles continuously.

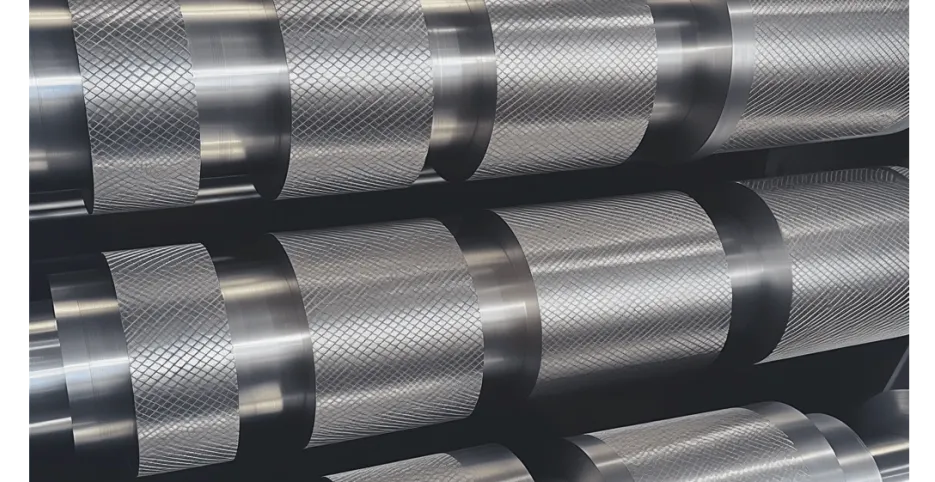

CNC TURNING

The CNC turning process is a manufacturing method where bar material is secured in a chuck and rotated. During this process, a tool is fed to the workpiece to remove material and shape it to the desired form. This method is also known as subtractive machining because it involves the removal of material. CNC lathes or turning centers come with various tooling options, power, and speed capabilities, which influence the types of parts that can be economically produced on them.

COMMON APPLICATIONS

Prototype in material that’ll be use during production and viability of design.

Produce small and intricate parts.

Complex pieces that have

SWISS CNC MACHINING

A Swiss machine, also known as a Swiss-type lathe or Swiss automatic lathe, is a precision manufacturing tool that feeds bar stock through a guide bushing, providing firm support and allowing for the rapid and accurate production of extremely small parts. Unlike traditional CNC lathes, where the material rotates in a fixed position, a Swiss lathe allows the material to move back and forth along the Z-axis while various cutting tools shape the part. This method produces parts with tight tolerances and complexity, ready for shipment without needing secondary operations.

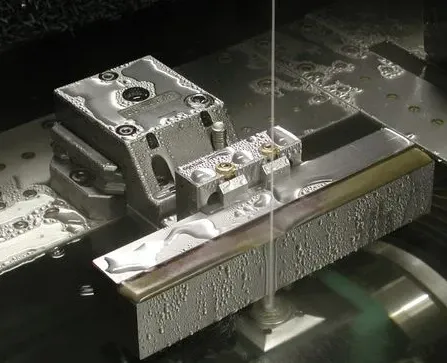

WIRE EDM MACHINING

Wire EDM machining is a high-precision method for cutting almost any electrically conductive material. It uses a thin, electrically charged wire held between upper and lower guides to form electrodes that cut the material. This process produces precision parts that meet exact dimensional tolerances. With perfect accuracy and repeatability, it can quickly produce prototypes, low-volume, or high-production parts. Wire EDM is ideal for highly accurate machining, making delicate and intricate parts, and achieving square-edged internal cuts that are difficult with other methods.

METAL MATERIALS

Aluminium, Stainless Steel, Alloy steel, Titanium, Copper, Tool Steel

+ much more

Don’t miss out on our services!

When you’re ready, we can assist you in selecting the best options for rapid prototyping or production quantities. Reach out to us to start a productive collaboration and find effective solutions together.

Services

All our available services at the moment for you!

CNC Machining

High Precision, Efficiency Flexibility, Repeatability, Reduced Error

Sheet Metal Fabrication

Durability, Versatility Cost-Effective, Lightweight, High Strength

Surface Finishes

Corrosion Resistance, Increased Durability, Enhanced Hardness