Meeting Your Specific Material Needs

As a custom parts manufacturer, we offer a wide range of rare metals and plastic materials to meet your specific needs. Each material boasts exceptional strength, durability, and unique properties, making them ideal for various applications.

At YH-RUSH, we have the expertise and advanced machinery to handle these diverse materials with precision and efficiency. From design to production, we ensure the highest quality standards to meet your exact requirements.

Materials

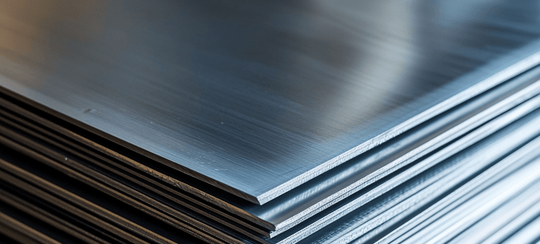

Aluminum

Aluminum alloy can be used for surface treatment such as anodizing and sandblasting. The color of aluminum alloy is silver white. The specific strength is close to that of high alloy steel, and the specific stiffness is higher than that of steel. It has good casting performance, good electrical and thermal conductivity, good corrosion resistance and weldability. It can be used as structural materials and is widely used in aerospace, aviation, transportation, construction, electromechanical, light chemical and daily necessities.

POM

The hardness of Delrin (POM, polyoxymethylene) is relatively high. Rockwell hardness reaches D80-85Z. It is a high hardness material in engineering plastics. In terms of hardness, POM is equivalent to ordinary carbon steel. In terms of other processing properties, POM can be used for bearings, gears and other parts that can replace steel. It has insulation, low moisture absorption and wear resistance that metal materials do not have.

Stainless Steel

Stainless steel is a kind of steel with stainless steel, corrosion resistance, air, steam, water and other weak corrosive media or stainless steel, and the chromium content is at least 10.5%, and the maximum carbon content is not more than 1.2%; The steel that is resistant to chemical corrosion medium (acid, alkali, salt and other chemical etching) is called acid resistant steel. Stainless steel has good weldability, polishing performance, heat resistance, etc. It can be used in the production of tableware, insulated cups, steel pipes, water heaters, drinking fountains, joints, rotating shafts, automatic screw lathes, pump and valve parts, screws and nuts, etc

Polycarbonate

Polycarbonate(PC) is a thermoplastic with high toughness, excellent impact strength and good machinability. It can be disassembled for processing. PC materials can be used for injection molding, extrusion, molding, thermoforming, printing, and machining. PC has high hardness and good light transmittance and can be chemically polished, which is fumigated and transparent. But it will turn yellow all year round under light or high-temperature conditions.

Brass

Brass has good mechanical properties, good machinability, easy welding and corrosion resistance. It is famous for its plasticity, ductility, excellent thermal conductivity and conductivity. When it is exposed to various elements, it will form thin protective copper rust, which is relatively impermeable. Highly machinable alloys are ideal for parts requiring low friction. Common application industries: faucet accessories, fasteners, circuit breakers, electronic instruments, magnetrons, radiators, etc.

ABS

ABS is recommended for its scratch resistance, dimensional stability and other characteristics, moisture resistance, corrosion resistance and ease of processing. ABS material is also very environmentally friendly. Because it uses environmentally friendly chemicals, it has no toxicity or smell, and can also be electrically insulated, making it a very safe material. Glue can be removed at will. The materials are relatively cheap. But the ductility and high-temperature resistance are not as good as PA ABS is recommended for plastic parts requiring coating generally. We can customize all the colors you need.

Iron

The Iron structure is light in weight, but its strength is much higher than that of other building materials. Moreover, due to its good plasticity and toughness, the steel structure will not break suddenly due to accidental overloading and has strong adaptability to dynamic load.

Titanium

Titanium has metallic luster, ductility, low density, high mechanical strength and easy processing. Titanium alloy has good heat resistance and low temperature resistance. It can be used for a long time at 600 ℃ or higher, and can also maintain good ductility and toughness at - 196-253 ℃. The damping resistance of titanium is low, and its vibration attenuation time is the longest after vibration.

Common application industrie: Tuning fork, vibrating element, loudspeaker parts, cryogenic container, storage box equipment, clocks, glasses, jewelry, various precision parts, etc

Nylon

Nylon has good strength, impact resistance, thermal and mechanical properties, wear resistance, self-lubricating, slow burning and self extinguishing. The combination of nylon and glass fiber carbon fiber can improve the mechanical properties, dimensional stability, heat resistance and aging resistance.

Common application industries: automobile, aviation, electrical, cooling fan, industrial equipment, gear, bearing, etc.

Finishing: grinding, electroplating.

Don’t miss out on our services!

When you’re ready, we can assist you in selecting the best options for rapid prototyping or production quantities. Reach out to us to start a productive collaboration and find effective solutions together.

Services

All our available services at the moment for you!

CNC Machining

High Precision, Efficiency Flexibility, Repeatability, Reduced Error

Sheet Metal Fabrication

Durability, Versatility Cost-Effective, Lightweight, High Strength

Surface Finishes

Corrosion Resistance, Increased Durability, Enhanced Hardness