CNC MACHINING TYPES

YH-RUSH CNC machining services specialize in producing precision plastic parts according to your specific requirements. Whether you need a single prototype, small batch production, or large-volume manufacturing, we ensure tailored solutions for rapid prototyping and beyond.

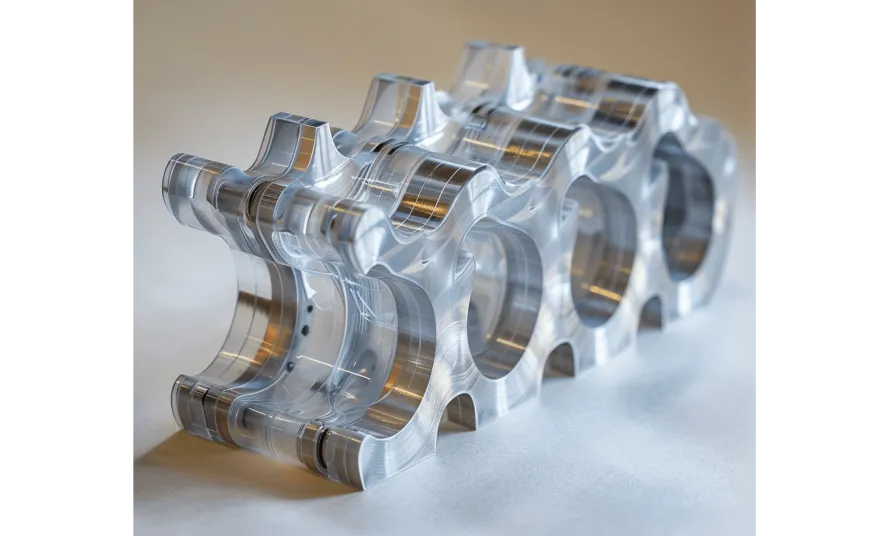

PLASTIC

CNC PROTOTYPE MACHINED PARTS

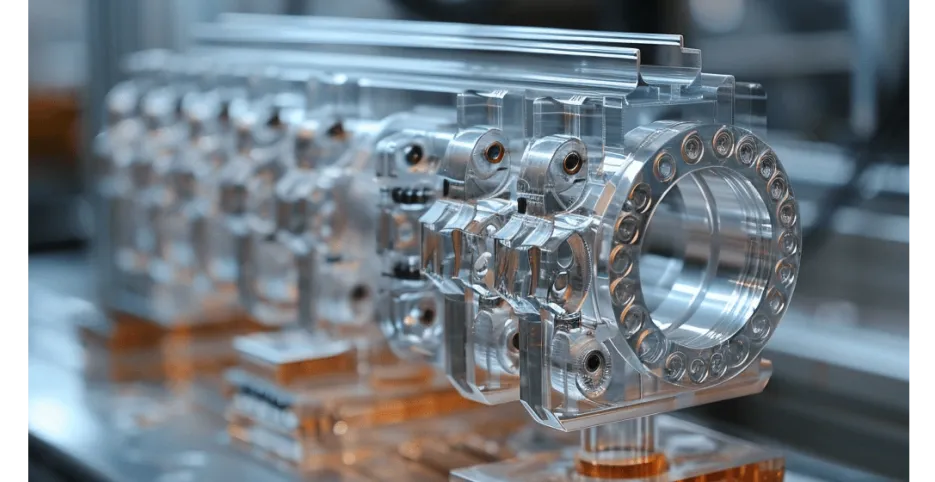

CNC MILLING

In order to make finished products, CNC milling entails employing a cutting tool to remove raw material from a designated solid metal or plastic block selectively. This manufacturing process makes use of 5-axis indexed milling and 3--4 axis milling, which move or spin on various planes to enable the tool to operate at a variety of angles continuously.

CNC TURNING

The CNC turning process is a manufacturing method where bar material is secured in a chuck and rotated. During this process, a tool is fed to the workpiece to remove material and shape it to the desired form. This method is also known as subtractive machining because it involves the removal of material. CNC lathes or turning centers come with various tooling options, power, and speed capabilities, which influence the types of parts that can be economically produced on them.

COMMON APPLICATIONS

Electronic device enclosures, instrument panels, protective covers

Gears, pulleys, bushings, guides

Surgical instrument components, diagnostic equipment enclosures

PLASTIC MATERIALS

ABS, POM, PEEK, PMMA, PC, PTFE, Nylon

+ much more

Don’t miss out on these amazing deals!

When you’re ready, we can assist you in selecting the best options for rapid prototyping or production quantities. Reach out to us to start a productive collaboration and find effective solutions together.

Services

All our available services at the moment for you!

CNC Machining

High Precision, Efficiency Flexibility, Repeatability, Reduced Error

Sheet Metal Fabrication

Durability, Versatility Cost-Effective, Lightweight, High Strength

Surface Finishes

Corrosion Resistance, Increased Durability, Enhanced Hardness